In IF industry, in general, the melting furnace structure is divided into steel-shell with the magnetic, hydraulic furnace and aluminum-shell with reducer dump furnace.

STEEL SHELL FURNACE:

- With a long life (generally normal service life of more than 10 years).

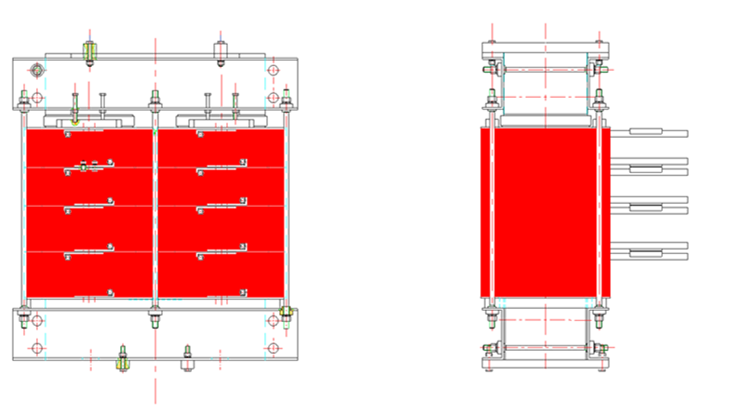

- Stability is excellent, because the use of magnetic conductor, the magnetic conductor has two functions: first, magnetic conductor with the top wire and induction coil firmly fixed, so that coil and magnetic conductor form a stable structure. Second, the magnet can create a magnetic barrier around the coil;

- Energy saving. Because of the magnetic guide furnace than aluminum shell furnace 3%-5% energy saving;

- Stable casting point. hydraulic tilting furnace device can well control casting angle, speed;

- Good safety performance. Due to the characteristics of a leakage alarm device and refractory mud layer), its good characteristics in the tonnage is greater than 2T are chosen steel shell structure.

ALUMINIUM SHELL FURNACE:

Aluminum Shell furnace is a simple structure form, and the service life is generally in 5-8 years, there is no magnet, lining top out mechanism, refractory clay layer, general use and 3T below the capacity. For example, a 5tons medium frequency furnace, full furnace molten iron, the overall weight of equipment up to 8-10T, if the choice of aluminum shell structure, when the reducer rotary furnace body to 95 degrees, the whole furnace will lean forward, the safety performance is very poor. Aluminum Shell furnace is suitable for short-time users, small tonnage.

ADVANTAGES OF STEEL SHELL FURNACE

1) Strong and durable, beautiful and generous, especially large capacity furnace body, need a strong rigid structure, from the angle of safety, try to use steel shell furnace.

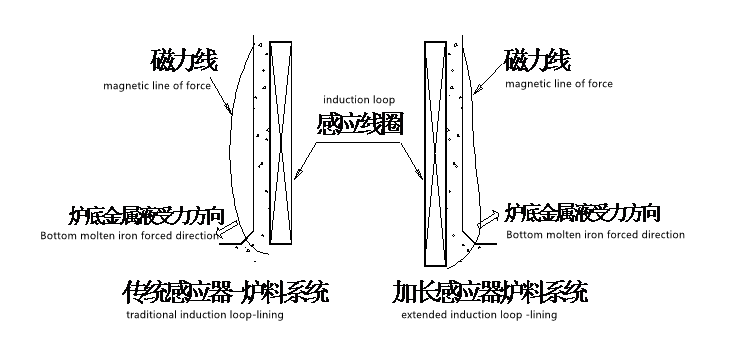

2) the magnetic yoke made of the silicon steel sheet can shield and emit the magnetic force line of the induction coil, reduce the magnetic leakage, improve the heat efficiency and increase the output, and save about 5%-8% energy.

3) the existence of furnace cover can reduce heat loss and improve the safety of equipment.

4) Long service life, aluminum in high-temperature oxidation more serious, resulting in metal toughness fatigue. In the foundry industry site, often see the use of about a year of aluminum shell furnace shell broken, and steel shell furnace, because of less magnetic leakage, equipment life greatly beyond the aluminum shell furnace.

5) the safety of the steel-shell furnace is much better than that of the aluminum-shell furnace. The aluminum-shell furnace is easy to deform because of the high temperature and heavy pressure.