STEP 3 # SEPARATING & CLEANING GRINDING BALLS

After molding, the casting mill balls are formed and then need to heat treatment. However, before that, need to break the balls from the pouring gates &runners, and cleaning the burned sand from the balls’ surface (when molding, there is much sand along with formed casting balls).

Some choose to separate by labor, but it will spend too much time and increase the labor cost. Here we recommend TWO methods to solve this problem.

1.One is manual way, using a simple machine – called separating of balls and cylpebs machine. For more further, most foundries add a sound-proof room with dust remover together.

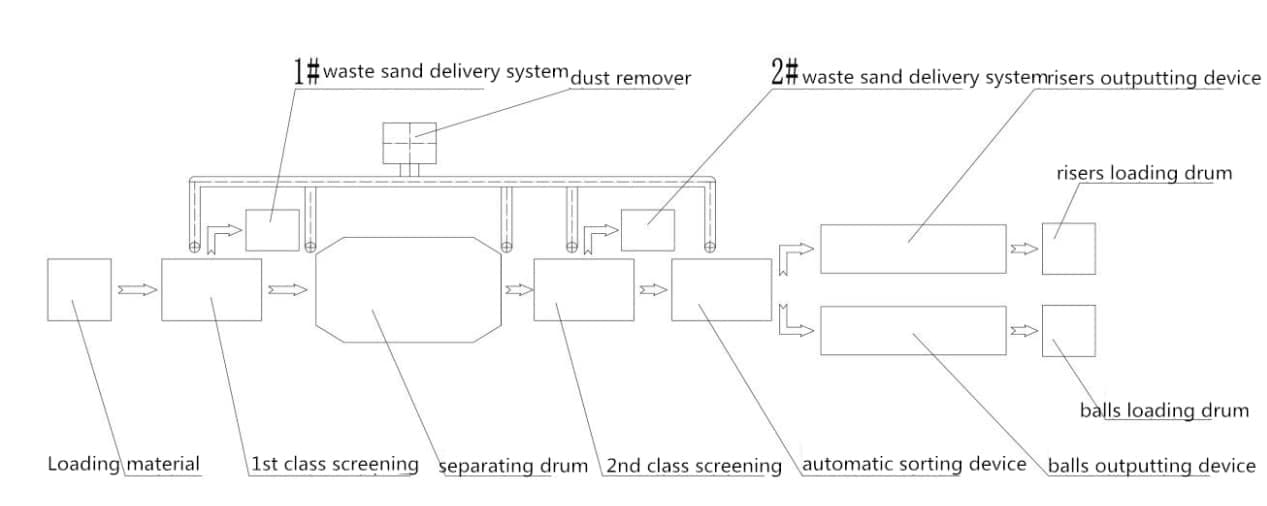

2. Another type is high auto way, placed the whole machine under the ground – called Automatic balls separating and sorting machine — safe, environment-friendly, labor saving.