STEP 4# HEAT TREATMENT PROCESS FOR GRINDING MEDIA

After balls separating and cleaning, grinding balls need to heat treatment. However, the different percentage of chrome, heat treatment process is not the same.

Types of Heat Treatment Process

For high chrome balls, Cr is over 10%, need quenching first and then tempering. For low chrome balls, Cr bellow 10%, only big size of balls need to be tempered. (Detailed process according to clients heat treatment technology.)

Also, for quenching, there are three methods: water, oil, and air quench. For grinding balls, the last two ways are the best. Moreover, for super high chrome balls, air quenching is welcomed than oil quenching. But, like 10-18%Cr, oil quenching is the most popular.

Quenching process: first heating the grinding balls up to the certain degrees in particular time, then quench directly to oil or air for several minutes.

Tempering process: heating the quenched grinding balls for a specific time in certain degrees.

So, you can see for both quench & temper; they have the same process is ‘Heating the Grinding Balls.’ The differences between them Only the heating temperature & and time. It explains why tempering and quenching Can share the same furnace.

Types of Heat Treatment Plants

There are two different types of heat treatment machine.

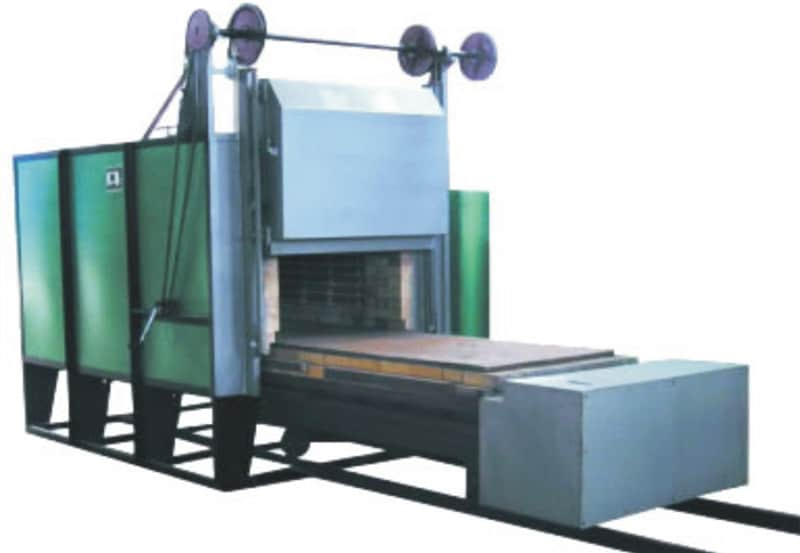

One is the car bottom type. This plant can process 4-6tons grinding balls per day; the power is electricity; semi-auto type; investment costs are low.

Another tunnel type is more suitable for more massive daily productivity, can meet the requirements of 10tons to 30tons/day.

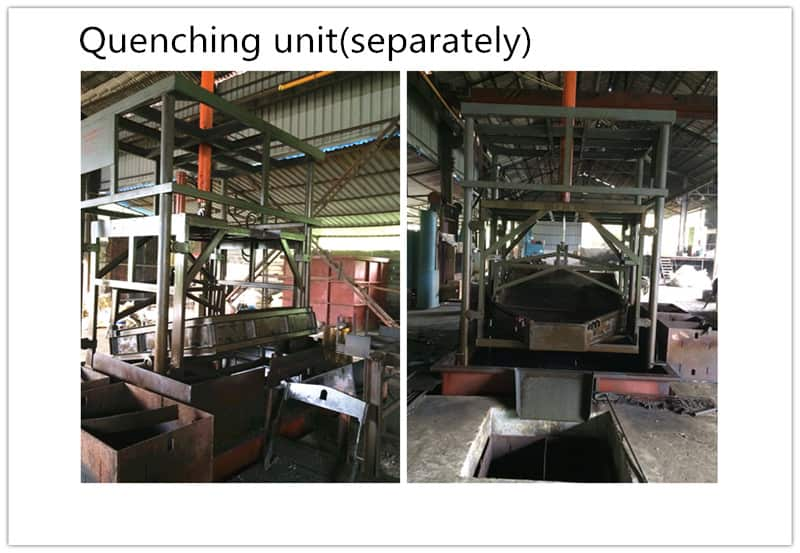

Please note, So what we mean by the difference between the two types of furnaces is the difference between the heating furnace and not the quenching unit. The heat treatment yield is determined by the size of the heating furnace rather than the Quenching Unit. Quenching unit is the SAME.

Here are detailed descriptions of the two furnaces.