NATIONAL STANDARD OF THE GRINDING BALLS IN CHINA (9)

Appendix B (Normative Appendix)

Measurement and calculation of the grinding balls broken rate

Under the normal working condition of the ball mill, the ball mill runs from 720h to 3000h (according to the working conditions, and the specific time is agreed by both the supplier and the buyer). Accumulated the mass of the broken balls during the ball mill operation, call it as the mass. The broken balls left in the ball mill are then picked up, weighed, and the total weight of the balls used during this period is measured.

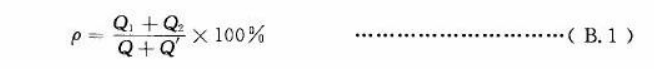

The fraction of broken balls is calculated according to the following formula (B1):

ρ ——broken rate,%;

Q ——initial loading balls weight,t;

Q’ ——Quantity of the grinding balls during the normal working,t;

Q1 ——The mass of the broken balls during the normal working,t;

Q2 ——Top ball mill and do the test, the mass of the broken balls in the ball mill,t.

Appendix C (Normative Appendix)

Calculation of the grinding balls consumption

Under the normal working condition of the ball mill, the ball mill runs from 720h to 3000h (according to the working conditions, and the specific time is agreed by both the supplier and the buyer).

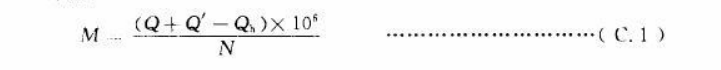

The consumption of the grinding balls is calculated according to the following formula (C1):

M — ball consumption of casting grinding ball (g/ton);

Q — The quality of the grinding balls in the initial ball mill, t;

Q’ –— normal operation to add the quality of the grinding ball, t;

Qh –– The mass of the reusable grinding ball, t;

N — Total mass of material input in the grinding process, t.