STANDARD OF THE CHROME ALLOY CAST GRINDING BALLS IN BUILDING MATERIALS INDUSTRY (3)

3.Terms and definitions

The terms and definitions established in GB / T5611, GB / T 17445 and the following shall apply to this standard

Medium Chromium abrasion-resistant cast grinding balls

The eutectic carbides are mainly (CR, Fe)7C3 and (CR, FE)3C cast grinding balls with chromium content more than 5% and less than 10%

4.Products types

4.1 According to the chrome content

Based on chrome contenting, casting grinding balls can be divided into low chrome balls, medium chrome balls and high chrome balls. And there are 5 types of the grades of the balls. Same grades grinding balls can be divided into un-quenched and quenched balls.

4.2 According to the diameter

Based on the grinding balls diameter, recommending 16 types of the balls. The diameter deviation for Dia10-dia25mmm and dia30mm to dia120mm grinding balls should be accord with the requirements of CT9 and CT10 grades precious rules in GB/T6414-1999

(Table 1, unit: mm)

|

ITEM |

Specification | |||||||||||||||

| D10 | D12 | D15 | D17 | D20 | D25 | D30 | D40 | D50 | D60 | D70 | D80 | D90 | D100 | D110 | D120 | |

| Deviation diameter | +1.0

-0,5 |

+1.5

-1.0 |

+2.0

-1.0 |

+2.5 -1.0 |

||||||||||||

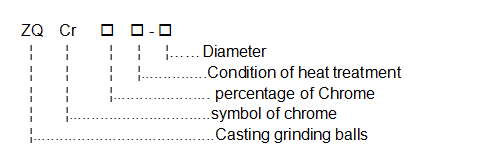

4.3 Representation of the brandfor the casting grinding balls

4.3.1 Using ‘ZQ’as the casting grinding balls

4.3.1 The code only shows the chrome contents and the condition of the heat treatment. A means quenched, B means un-quenched.

4.4 The code of the casting grinding balls

4.4.1The code-name of the cast grinding ball is indicated by the cast grinding ball grades plus the diameter.

4.4.2 The meanings of the symbols and numbers:

4.4.3 The example

Brand ZQCr15A, diameter 100mm casting grinding balls, marked as: ZQCr15A-100