Casting Production of Chrome Series Cast Iron Grinding Balls (1)

ZHANG Zhou1,LUO You-gen2,YING Gen-peng3 (1.Hangzhou Xuelin Science- Technology Development Service, Hangzhou 310012, China; 2. Longyou Hengshan Steel Ball

Factory, Longyou 324406, China; 3. Hangzhou Aobao Chemical Co. Ltd., Hangzhou 310012, China)

Abstract:A brief introduction was made to the chemical compositions, matrix structure, mechanical properties, and melting process of chromium series cast iron grinding balls. The particularities of their melting process and molds were analyzed, and the new market requirements were pointed out.

Keywords: chrome series cast iron grinding balls; wear resistance; melting process; casting mold

With the increase of grinding balls required by metallurgical mines, building materials cement, thermoelectric grinding coal, chemical powder, nuclear material industry, non-ferrous metal raw materials, and blast furnace pulverized coal, the production scale of grinding balls has developed rapidly in China. The melting equipment and casting process have been improved continuously. Metal Mold, Lost-foam casting, Cupola – dual induction furnace, or single induction furnace melting have been widely used. Furnace charge is mainly produced by the mill waste steel scrap pressure block and mechanical processing of steel scrap, such as around Sichuan to Vanadium Titanium Molybdenum Copper Grinding ball mainly; In the coastal areas, the recovery of machine tools, motor casings, scrap steel, and scrap is mainly in the scrap steel market, and the recovery of micro-alloyed low-chromium balls is mainly; in the western regions of Ningxia and Qinghai, the recovery of the chromium-nickel system is mainly; in some areas of Jiangxi, the recovery of manganese and trace chromium is mainly.

1.The characteristics of the chrome alloyed series grinding balls

(1)The low chromium alloy white cast iron grinding ball includes low chromium molybdenum copper, low chromium-vanadium titanium, low chromium copper, low chromium phosphorus copper titanium, and other W, V, P micro-alloyed low chromium white cast iron, etc.

If the diameter of the ball is more than 60mm, the ball can be melted in Cupola, double melting in induction furnace, cast in Metal Mould, quenched and tempered; if the diameter of the ball is less than 50mm, the ball can be melted in Cupola (also useful for improved three sections melting) and cast in a metal mold, isothermal hardening.

When used in dry grinding of cement, the wear resistance of low chromium grinding ball is 7 ~ 9 times that of ordinary steel, and 2 ~ 3 times that of ordinary steel ball when used in wet grinding of ore, and 1 ~ 1.5 times that of medium carbon and high carbon quenched and tempered steel ball.

(2) The cost and selling price of medium and high chromium alloy cast iron grinding ball are higher because the content of w (CR) is much higher than that of low chromium ball. For Dry grinding, it has the advantages of reducing consumption, saving the ball and increasing efficiency, and for wet grinding ore (bauxite, gold ore, copper ore, iron ore, etc.), the wear resistance of medium-high chromium grinding ball in use is 8 ~ 10 times higher than that of ordinary steel ball, and corrosion resistance.

2.The chemical composition of the chrome alloyed series grinding balls

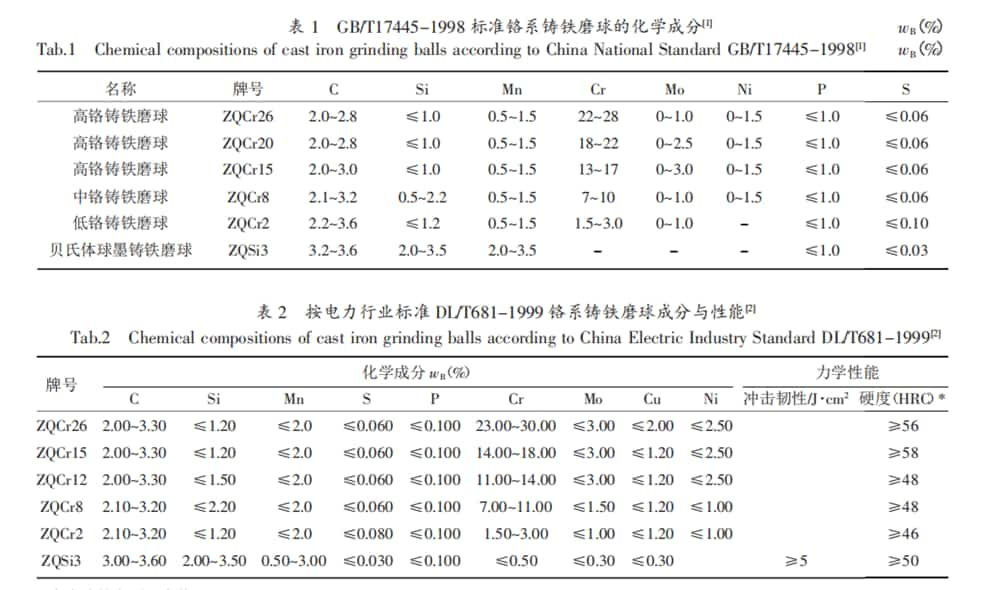

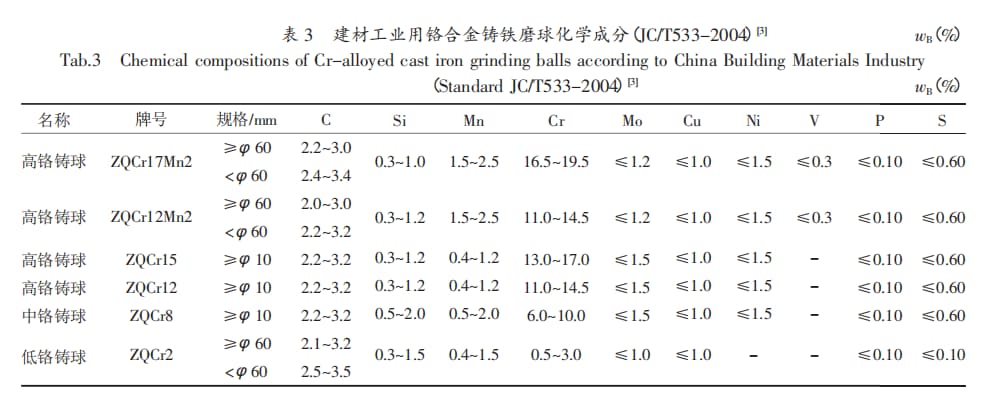

The chemical composition of cast grinding balls according to GB/T17445-1998 is shown in Table 1. DL/T681-1999 by the power industry standard, See Table 2. The chemical composition TC/T533-1999 of cast chromium alloy grinding balls for the building materials industry is shown in Table 3.