ANALYSIS AND COUNTERMEASURES OF THE CAUSES AFFECTING THE SURFACE QUALITY OF CASTING GRINDING BALLS (2)

3.Causal Analysis

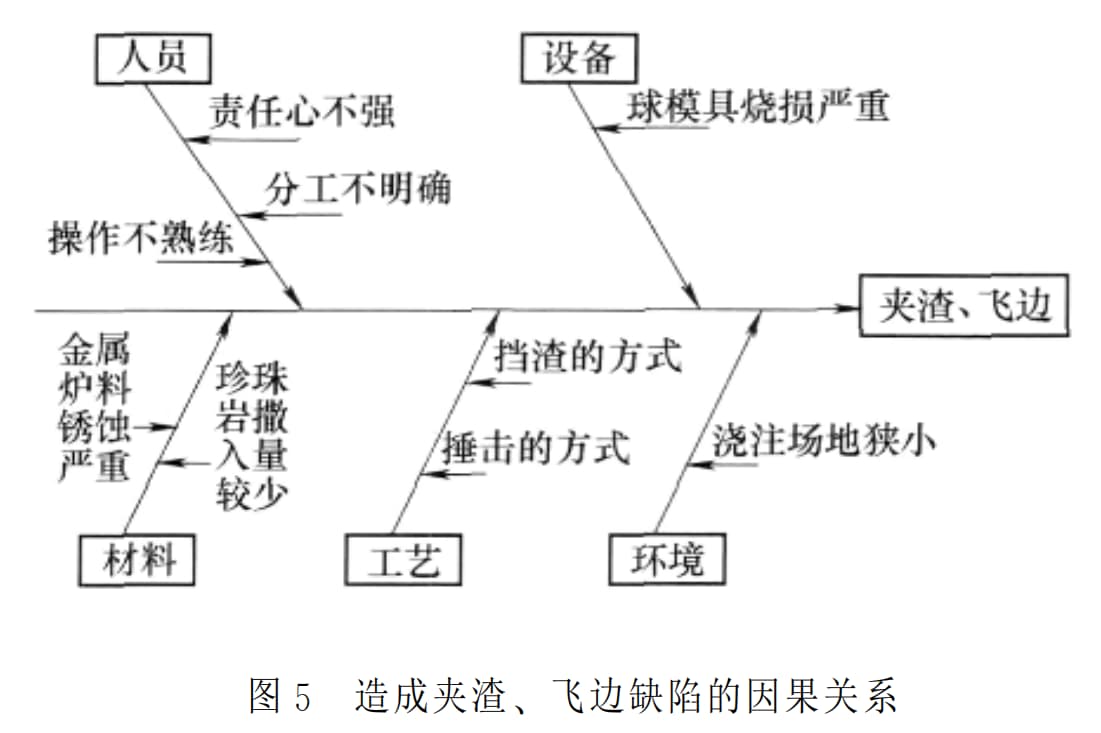

According to the actual situation of grinding ball production, the cause and effect analysis chart (see Fig. 5) is used to analyze and study the factors which may lead to slag inclusion and fly edge defects from five aspects: man, machine, material, method, and ring.

4.The important cause confirm

Because the cause and effect analysis chart causes the slag inclusion and the flying edge flaw main reason may induce several points.

- The personnel is not skilled in handling. The operator of the post of the operation of the degree of proficiency is crucial; it not only affects the Labor efficiency but also affects the appearance of the ball quality. In pouring, if the pouring workers can master the slag removal method, effectively block the slag in the ladle so that it is not brought into the cavity molten iron, slag inclusion defects will not occur. In cleaning shovel, if the cleaner can effectively remove the flash and burr so that it is no longer residual in the grinding ball, the flash defect will not occur.

- The mold is badly burned. The grinding ball mold has been working under the condition of high temperature for a long time. The Oxidation and growth of the surface of the ball socket have resulted in the burning of the surface of the ball mold, especially at the seams of the upper and lower molds, and the grinding balls produced by the mould with the serious burning of the seams, the flash defect is serious and difficult to remove.

- The amount of Perlite is relatively small. When perlite as a slag-collecting agent is scattered on the surface of the liquid iron, the slag and the perlite stick together, which makes the slag and the liquid iron separate, the amount of perlite scattered is less, the slag and the perlite on the surface of the liquid iron can not stick together well, it is not easy to carry the slag into the mold cavity when the slag is stripped clean, and cast and the slag inclusion defect is formed.

5.Countermeasures

In view of the above-mentioned main reasons, the countermeasures are formulated as follows:

1) personnel, the pouring workers for slag-blocking training, shovelers for shovelling training

2) for equipment, replace the badly burned ball mould

3) material, increase the amount of perlite poured into the ladle