Application of high chrome alloy grinding balls in cement mill (2)

3.Industrial application test

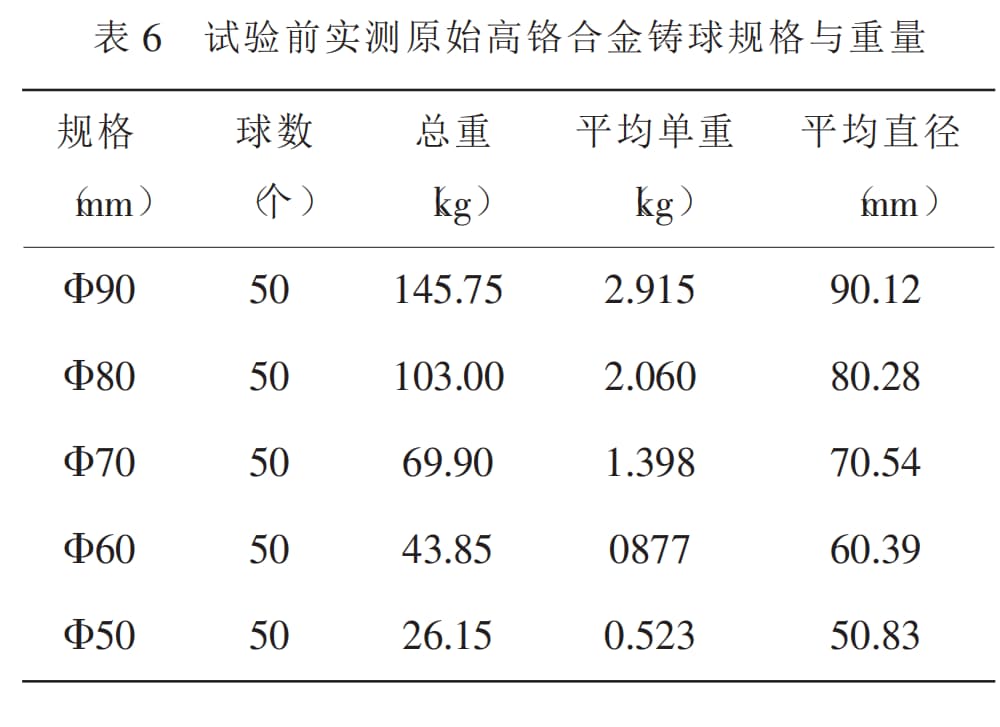

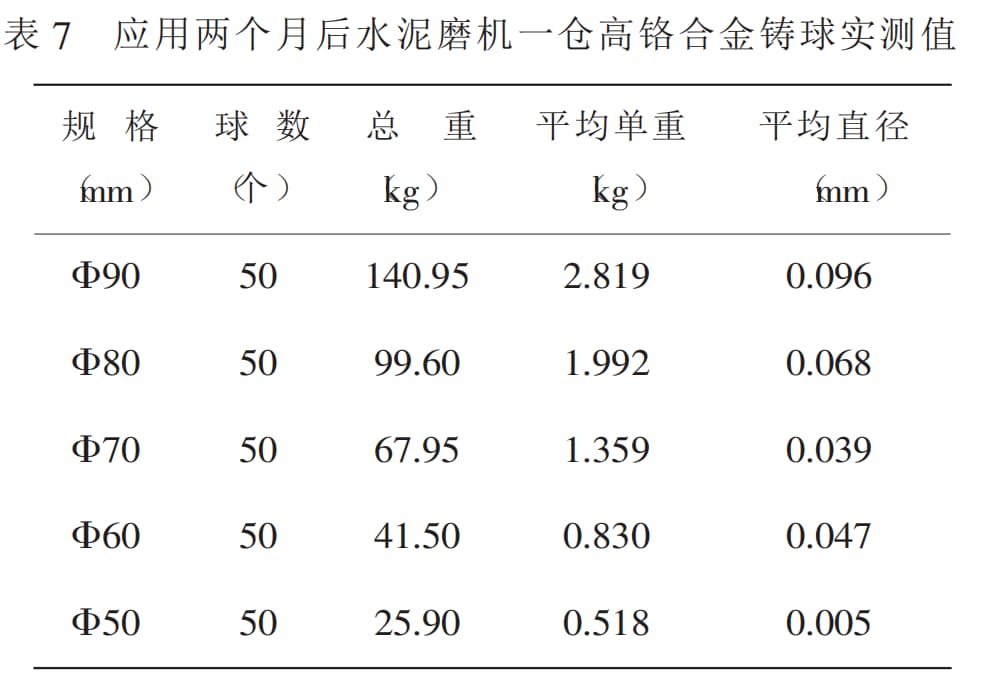

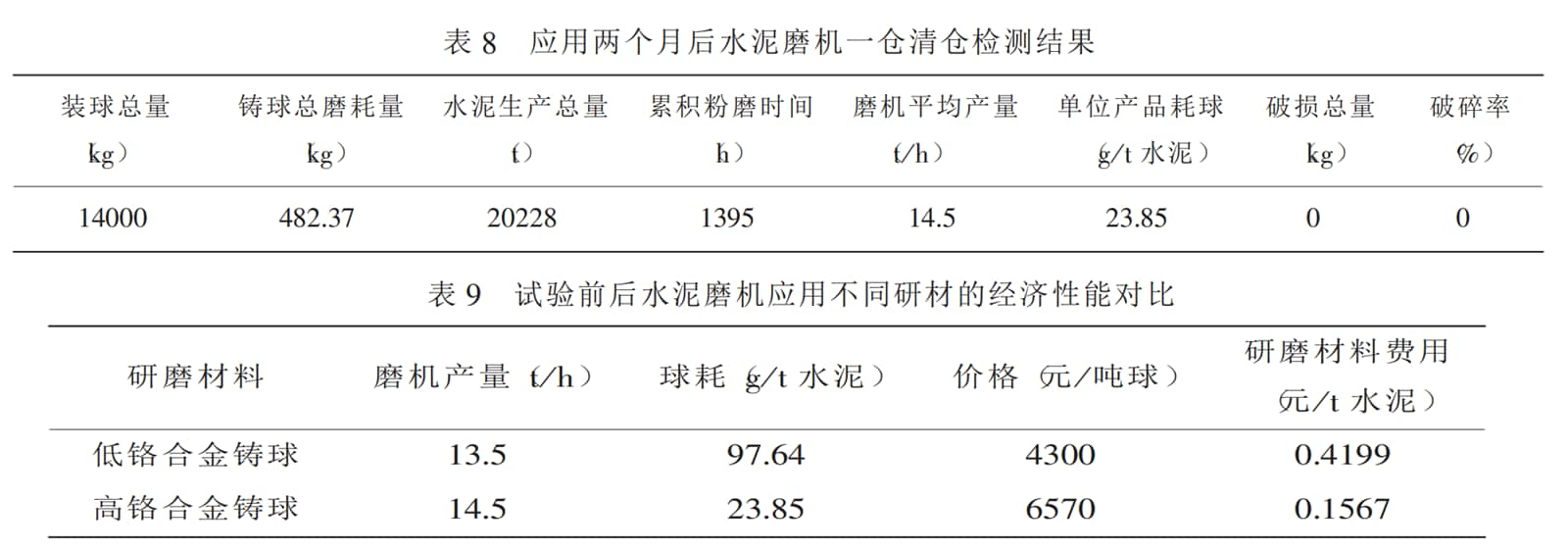

Since April 1, 2001, when the cement mill gave up the use of low-chromium alloy cast ball to replace the use of high-chromium Alloy cast ball, two months after the cement’s normal operation mill under suitable technological conditions. On June 1, 2001, the test was carried out by Fengjiang Cement Research Center. The test results are listed in Table 6, Table 7, Table 8, and Table 9.

On June 16, 2001 and August 1, 2001, 90mm high chromium alloy casting balls were added in the first warehouse of the cement mill respectively, except for 0.2t of other specifications, casting balls were not added. As of August 31, 2001, the total production strength grade was 42.5R common silicon cement 50100t.

4.Economic benefit of high chromium alloy casting ball used in cement mill

4.1 The ball consumption of the mill is reduced

The ball consumption of cement mill can be reduced by 73.79 g/t, if the annual output of cement mill is 120,000 t, the annual saving of steel is 8.85 t, and the ball consumption is low, the cost of cement grinding material decreased by 0.2632 Yuan/t, and the annual cost of cement grinding material could be saved by 31,600 yuan.

4.2 The output of the mill is increased and the power consumption is reduced

Comparing the high chromium alloy cast ball with the low chromium alloy cast ball, it can be seen from table 9 that the output of the mill is increased by 1.0 t/h under the strict control of the fineness of cement products ≤1.8% and the specific surface area ≥380 m2/kg, this is the result of a further reduction in ball wear and the ability of the mill to operate over a long period of time in a continuous ideal grading. Increasing output means reducing the power consumption of the mill.

4.3 The cleaning times of the reverse mill are reduced, and the running rate of the mill is increased

From Table 9, the service life of high chromium alloy cast ball is 4.09 times that of low chrome alloy grinding ball. The mill used a low chrome alloy warehouse, casting grinding ball, every 4-6 months back grinding screen once, using high chrome alloy, casting ball, and every 6-9 months back grinding screen. Reduce the number of backwash clearance, which means to improve mill throughput.

5.Conclusion

In summary, according to the test results of using high chrome alloy grinding ball in the cement ball mill, under the same production technology, the mill should use high chrome alloy grinding ball with higher grinding efficiency, lower ball consumption, and lower wear rate than using low chromium alloy cast ball, it can effectively stabilize the gradation, reduce the grinding cost of cement and improve the economic benefit. Therefore, a high chrome alloy grinding ball is a kind of replacement product of the grinding body.