NORMAS PARA LAS BOLAS DE MOLIENDA DE ALEACIÓN DE CROMO FUNDIDAS EN LA INDUSTRIA DE MATERIALES DE CONSTRUCCIÓN (7)

Apéndice A (anexo informativo)

Tasa de rotura y tasa de desgaste de las bolas de molienda de fundición.

A.1 En las siguientes condiciones normales de funcionamiento, la tasa de rotura de bolas y la tasa de desgaste del molino de bolas que funciona durante 2000 h y 3000 h se muestran en la Tabla A. 1.

- Molienda del cemento portland normal

- La temperatura de molienda del cemento no debe superar los 120 ℃.

- El tamaño de grano del clínker es inferior a 80 ≤ 20 mm.

- La superficie específica del cemento no debe exceder los 340 mm2/kg.

- El diámetro del molino de bolas es de 2,8-3,2 m.

- La capacidad de producción del molino de bolas y la capacidad de carga de las bolas de fundición deberán cumplir con lo establecido en JC 334.1–1994 y las reglamentaciones relacionadas.

Cuadro A.1

| ARTÍCULO | TIPO | ||

| Bolas de alto contenido en cromo | Bolas cromadas medianas | Bolas de bajo contenido de cromo | |

| Tasa de rotura de bolas de una sola cámara: % | ≤0,8 | ≤1,5 | ≤2,5 |

| Tasa de desgaste de una sola cámara: g/tonelada de cemento | ≤30 | ≤50 | ≤80 |

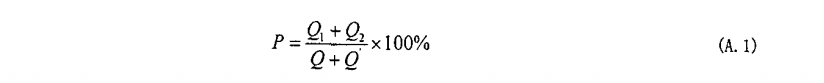

A.2 Tasa de rotura (fórmula de cálculo A.1)

p ——-tasa de ruptura, unidad (%);

Q ——masa de carga inicial de las bolas de molienda, unidad (tonelada);

Q'——en condiciones normales de trabajo, sumando la masa de las bolas de molienda, unidad (tonelada);

Q1——La masa de bolas rotas descargadas por el molino de bolas durante el funcionamiento normal, unidad (tonelada);

Q2——Detener y verificar la calidad de las bolas rotas en el molino de bolas, unidad (tonelada).

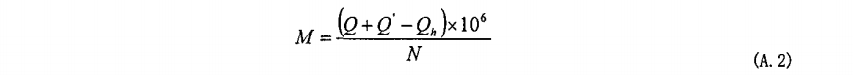

A.3 Tasa de desgaste (fórmula computacional A.2)

METRO——tasa de desgaste de las bolas de molienda, unidad (g/tonelada);

Q—masa de carga inicial de las bolas de molienda, unidad (tonelada);

Q'——sumando la masa de las bolas de molienda en condiciones normales de funcionamiento, unidad (tonelada)

Qh—— puede reutilizarse la masa de la bola de molienda, unidad (tonelada);

norte——En el proceso de molienda, la masa de todas las cosas agregadas, unidad (tonelada)