Experimental study on Cr12 high chromium cast balls (2)

2.Test results and analysis

2.1 Effect of modification on the microstructure of Cr12 high chromium cast balls

By comparing the enlarged photograph of high chromium cast ball CR12, without modification and after modification, it can be seen that without modification, the high chromium cast ball Gold Carmen structure, in which the carbonization, the materials are all, have, intermittent, reticulation tendency: after modification, the carbide of the gold, phase group, and texture is in lump shape, and the distribution is more isolated and even.

2.2 The effect of thermal treatment on the properties of the high chromium cast balls

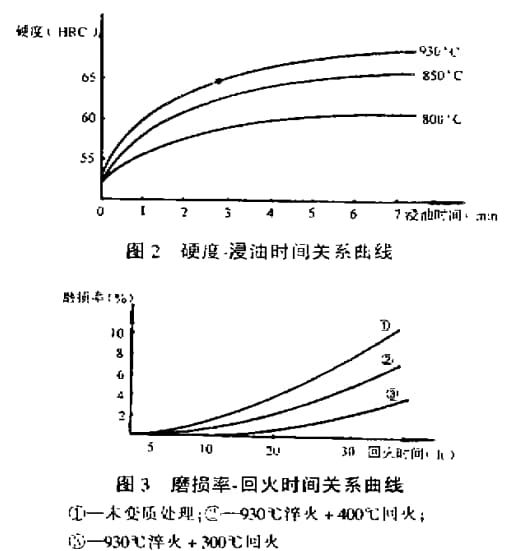

The effect of the quenching process and technology on cast balls’ properties is shown in Fig. 2. The quenching temperature is 930 °C. The hardness can reach over HRC65 when the temperature is kept for 3 h, and the oil is immersed for 4 min.

When the quenching temperature is higher than 930 °C, a large amount of mixed microstructure of martensite and austenite will be produced after quenching due to the presence of retained austenite.

The main purpose of tempering is to improve the wear resistance of the cast ball. In the tempering process, when the temperature exceeds 300 °C, the hardness begins to decrease with the increase of temperature, and the wear rate increases with it. When the tempering temperature exceeds 400 °C, the pearlite structure will be formed, and the hardness begins to decrease sharply, so the tempering temperature should be controlled below 300 °C.

2.3 Mechanical properties under different casting processes

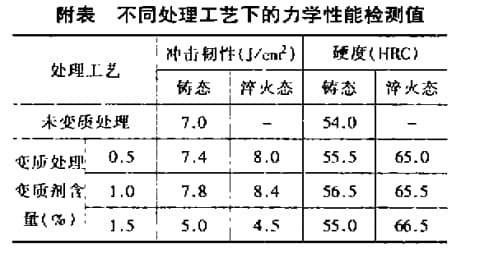

The testing values of mechanical properties under different treatment processes are listed in the attached table. After modification, carbide’s morphology is improved, the splitting effect of carbide on the matrix is obviously weakened, and the toughness is increased; at this point, 1.0% of the modifier is the most suitable. When the amount of modifier exceeds a certain amount, the amount of carbide increases, so the impact toughness decreases.

After quenching heat treatment, martensite transformation basically occurs, which greatly increases the hardness value.

2.4 Damage Test

The experiment was carried out on a 2.5 m diameter damage testing machine, and the running time was 10h, 20h, and 30H, respectively. The results were consistent. The unmodified cast balls had very serious exfoliation and high crushing rate, while the modified cast balls had very little exfoliation, and the breakage rate, it’s low.

2.5 Application

CR12 high chromium cast ball was tested in a large cement plant. The test was carried out in a bin of the mill with a diameter of 3.8 m × 13.5 m, the running time was 5500h, the crushing quantity was 371000t, and the total ball quantity was 56t. The test results were as follows: the unit wear was 16.5 g/l, which was 2/3 of the high chromium cast ball previously used; the effect was very obvious, has now been widely used.

3.Conclusion

1) after modification and quenching treatment, the impact toughness and hardness of CR12 high chromium cast ball are further improved, but the addition of modifier must be moderate

2) Cr12 high chromium cast ball after the modification has good wear resistance, no deformation, no loss of circle, and good effect in the grinding industry.

3) the CR12 high chromium cast ball, because reduces the Cr addition amount, and does not need to add expensive metal elements such as Mo and Cu, dramatically reduces the manufacturing cost, has the huge economic benefit and the social benefit.