NATIONAL STANDARD OF THE GRINDING BALLS IN CHINA (8)

APPENDIX A (Normative Appendix)

Grinding Ball Impact Fatigue Life Test Method

Falling-balls test to check the impact fatigue of the grinding balls (Hereinafter referred to falling ball test), under the laboratory condition, simulated the impact process for the grinding balls in the ball mill. Impact times counted by the counter. Impact failure time shows the grinding balls working life in such condition.

A1 Falling balls tester type: MQ; the falling distance: 3.5m

A2 The experimental subject are dia100mm grinding balls

A3 For falling balls test, 16pcs casting grinding balls shall be taken as test balls from the batch inspected, and more than three casting grinding balls shall be taken as replacement balls and marked on the surface of the replacement balls.

A4 The falling ball test is carried out in normal temperature.

A5 The failure judgment and test procedure of casting grinding ball are as follows:

A5.1 Failure judgement of the casting grinding balls

- the average diameter of spalling layer on the surface of casting grinding ball (the average value of maximum diameter and minimum diameter) is more than 20mm, and the thickness of middle part is more than 5mm.

- The grinding balls cracked along with the middle.

A5.2 Test Procedure

A 5.2.1 Polish the edges of the test ball and the replacement balls, or clean the surface in the cleaning roller. Check the tester’s working condition.

A 5.2.2 start by placing 12 test balls into the bend, then starting the machine and gradually placing the remaining 4 balls into the circulation transportation system from the glide path.

A 5.2.3 Clear the counter, digital dial to a predetermined number (8000)

A 5.2.4The test personnel should observe carefully on the spot, when it is found that one test ball has failed according to 1) or 2) in A 5.1, take out the failed ball and put in a replacement ball until the third failed ball appears. Separately record the cumulative impact times in the falling ball machine system when the three test balls failed. If the number of failed balls in the test does not reach the number of failed balls, but the added replacement balls have been destroyed, the failed replacement balls shall not be counted.

A.6 Requirements for impact fatigue test life of grinding balls

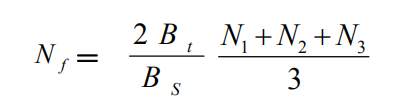

A6.1 The impact fatigue test life of grinding ball is determined by the following formula

Nf– Impact Fatigue Test Life (number of times) of the grinding ball;

N1 — The number of times the counter records when the first test ball fails;

N2 — The number of times the counter records when the second test ball fails;

N3 — The number of times the counter records when the third test ball fails;

Bt–The number of cast grinding balls in bend Pipe;

Bs– Total number of cast grinding balls in the test system.

When processing the data, the decimal part is filled in the test report with the integer value according to the requirements of GB/T 8170. In the test report should indicate the failure of the failure ball, and record the test temperature.