Brief Introduction

Hexin company is a professional grinding media equipment supplier, like automatic grinding balls molding line, heat treatment machine, balls separating machine, etc. Hexin technical team has over 20 years of manufacturing experience and grinding balls manufacturing technology. The molding line has occupied over 95% of the Chinese market, served hundreds and thousands of foundries.

The grinding balls molding line is a good producer to produce qualified grinding balls, whatever the raw material is. It combines the sand-lined metal mold technology with high productivity. The produced size scope is from dia30mm to dia130mm, good to install in cement, mines, and thermal power station. Comparing with the green sand casting line produced grinding balls, grinding balls molding line produced are finer and better mechanical properties, especially for the size of the balls over 40mm.

Main Components & Working Process

The grinding balls molding line consists of molds opening and closing device, flipping dumping device (double working position), vibrating waste sand cleaning machine, sand shooting device(four-working position), molds pushing device, running orbits, pouring machine, and electrical control cabinet, etc.

Working process:

- The cleaned top and bottom metal mould coated with precoated sand separately.

- The top and bottom metal mould closed together.

- Pouring the molten iron (raw material of grinding media) into the closed mould (formed the balls).

- Open the top mould, then the balls loaded on the bottom mould.

- Pouring out the grinding media from the bottom mould.

- Clean the waste precoated sand which left in the chamber of the mould (both top and bottom mould) by Vibrating Device

- Clean the waste precoated sand AGAIN by Operator (Checking)

- Back to step ①

Characteristics

1) Low producing costs, low labor tensity

2) Maintenance fees are low, the electrical system is the main easy-consumption parts

3) Long lifetime of the metal mold, at least 5 years

4) Functional, it can produce two sizes of the balls at once

5) Environmental friendly, the pre-coated sand can be recycled.

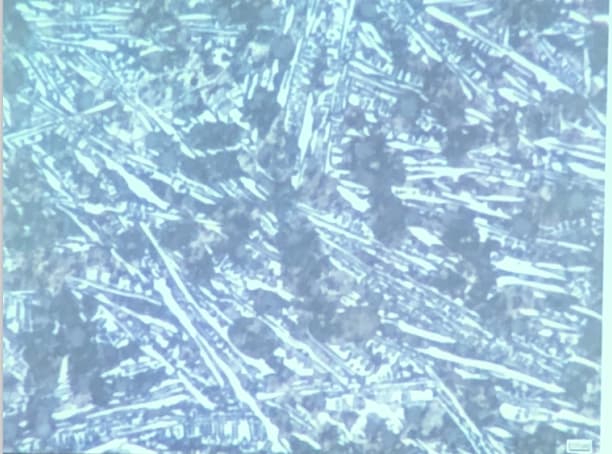

6) Good quality of the grinding balls, compared with manually made grinding balls, making machine made are much better, no rags, no disorder, fine microstructure.