Solidification Temperature Field Numerical Simulation of Wear-Resistant Cast Ball Based on the MAGMA (2)

3.Improved plan

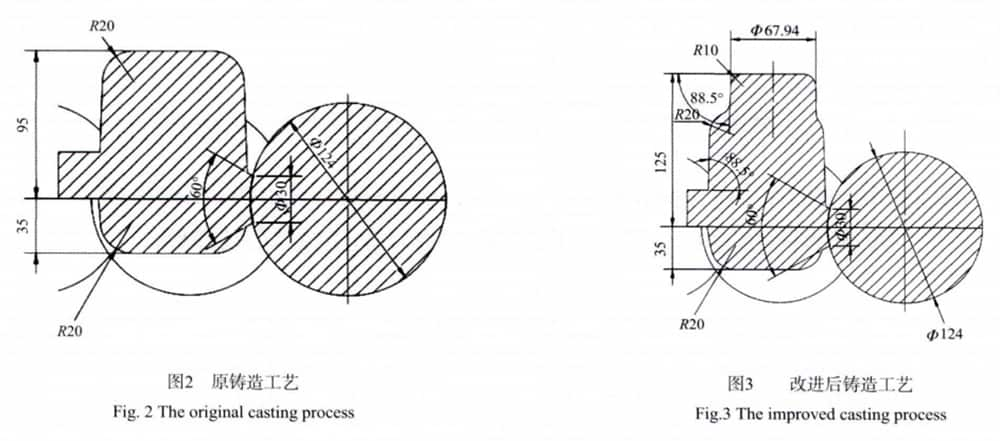

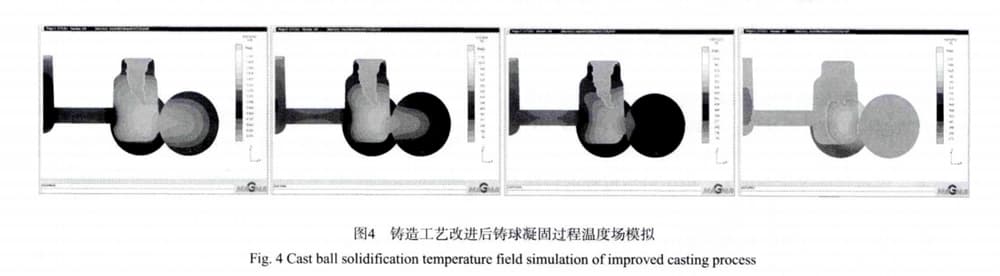

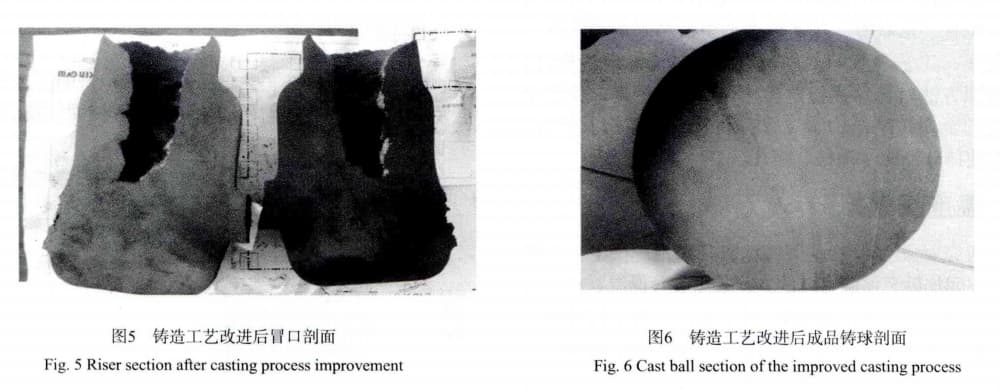

By improving the casting process, as shown in Fig. 3, the temperature field in the solidification process of the cast ball is changed to eliminate the defects. The improvement scheme is as follows: raising the riser, the diameter is 67.94 mm, the height is 30 mm, and the feeding capacity of the casting is increased to a certain extent. As shown in Fig. 4, it can be seen that the isotherm of the actual solid line temperature does not form a closed loop in the cast ball, and the shrinkage porosity and shrinkage cavity can not be predicted. After the trial production, the riser and the casting ball are cut apart. As shown in Fig. 5 and Fig. 6, shrinkage porosity appears in the upper and middle part of the riser, which is consistent with the solidification process simulation, and the structure of the finished casting ball is very compact.

4.Conclusion

Based on the numerical calculation result of the solidification process of wear-resistant metal mold cast ball by temperature field numerical simulation software Magma, the wear-resistant cast ball’s shrinkage and porosity are eliminated by improving casting technology, and the quality of the wear-resistant cast ball is guaranteed.