STANDARD OF THE CHROME ALLOY CAST GRINDING BALLS IN BUILDING MATERIALS INDUSTRY (7)

Appendix A (informative annex)

The broke rate and wear rate of the casting grinding balls

A.1 Under the following normal operating conditions, the ball broken rate and wear rate of the ball mill running for 2000h and 3000h are shown in Table A. 1.

- Grinding the normal portland cement

- The grinding temperature of cement shall not be exceed 120℃

- Grain size of clinker is less thand80≤20mm

- The specific surface area of cement shall not be exceed 340mm2/ kg

- The diameter of the ball mill is 2.8-3.2m

- Production capacity of ball milland loading capacity of casting balls shall be in line with JC 334. 1–1994 and related regulations.

Table A.1

| ITEM | TYPE | ||

| High chrome balls | Medium chrome balls | Low chrome balls | |

| Single chamber balls broken rate: % | ≤0.8 | ≤1.5 | ≤2.5 |

| Single chamber wear rate:g/ton cement | ≤30 | ≤50 | ≤80 |

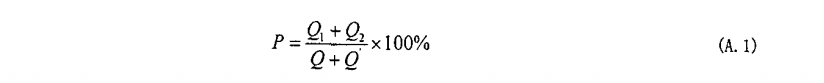

A.2 Broken rate (computational formula A.1)

p ——-broken rate,unit(%);

Q ——initial loading mass of the grinding balls, unit (ton);

Q’——in the normal working condition, adding the mass of the grinding balls, unit (ton);

Q1——The mass of broken balls discharged by the ball mill during normal operation,unit(ton);

Q2——Stop and check the quality of broken balls in the ball mill,unit(ton).

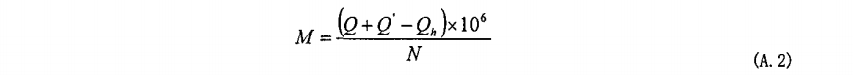

A.3 Wear rate (computational formula A.2)

M——grinding balls wear rate, unit (g/ton);

Q—initial loading mass of the grinding balls,unit(ton);

Q’——adding the mass of the grinding balls in normal working condition, unit (ton)

Qh—— can be reused mass of the grinding ball, unit(ton);

N——In the grinidng process, the mass of the all adding things, unit (ton)