Study on the application of high chrome grinding balls instead of low chrome grinding balls in molybdenum ore (2)

2.High chrome grinding balls application

2.1 High and low chrome balls contrast

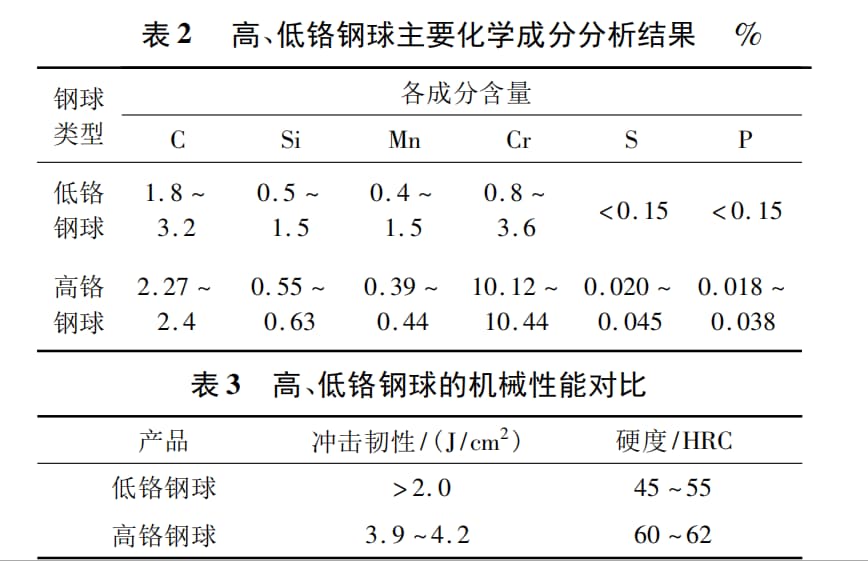

The production practice shows that the strength and wear resistance of the low chrome grinding balls are low and easy to be broken, which makes the broken ball rate and the out-of-round rate higher and has a particular influence on the grinding effect. The surface of high chrome grinding ball is smooth; the casting head is small, the quenching process makes its hardness high, not only wear-resistant, and good toughness. The results of chemical composition analysis of high and low chromium steel balls are shown in Table 2, and the mechanical properties are shown in Table 3

Due to the difference in chemical composition and mechanical properties between high and low chrome grinding balls, compared with little chrome grinding balls, high chrome grinding balls have precise dimensions, round geometry, high hardness, and excellent mechanical properties, and are wear-resistant and not easily deformed in use. A low round loss rate can maintain the stability of the ball mill grading for a long time.

2.2 Analysis of using effective

1) Improve your processing power. The processing capacity of 1 # ball mill is 342.57 t/h before changing to use, and it is increased to 402.60 t/h after changing to use. This is related to the further optimization of the high-pressure roller grinding system and the improvement of grinding efficiency due to the high chrome ball density and low roundness loss.

2) the unit consumption of grinding ball is reduced, the unit consumption of grinding ball is 0.808 kg/t before changing to high chrome grinding ball, and 0.370 kg/t after replacing, the unit consumption of grinding ball is reduced by 54.21%.

3) the grinding effect is improved. The content of coarse grade (+ 0.106 mm) and easy grade (0.106 ~ 0.037 mm) were decreased by 5.21 percentage points and increased by 2.08 percentage points. Split Point, basically back to the status quo ante.

2.3 Economical analysis

1) saving the cost of grinding

According to statistics, in 2017, the unit consumption of low chrome grinding balls of 1 # ball mill is 0.808 kg/t, the price is CNY3846 /t, the corresponding treatment cost of 1ton ore is 3.11CNY, the unit consumption of high chrome grinding ball after transformation is 0.370 kg/t, the price is 6600 CNY/t, the corresponding 1ton ore processing cost is 2.442CNY. 1 # ball mill can process CNY 3 million ore per year, according to this calculation, the cost of grinding ball can be saved CNY 2 million per year, the economic benefit is remarkable.

2) Reduce labor intensity.

Due to the drop in single consumption of grinding ball, the amount of grinding ball added per time is reduced from 6 tons to 3 tons.

3.Conclusion

1) when high chrome balls replace low chrome balls, the unit consumption of grinding balls decreases from 0.808 kg/t to 0.370 kg/t, the decrease rate is 54.21%, and the cost of grinding balls is saved CNY 2 million per year.

2) when high chrome balls replaced low chrome balls, the capacity of 1 # ball mill was increased from 342.57 T/h to 402.60 T/h, which was related to high chrome ball’s high density and low round loss.

3) the grinding effect is improved by using high chrome balls instead of low chrome balls.

(The Chinese version of this article is chosen from Morden Mining. This article only used for the study. )