The Manufacturing Process Research on Medium Chrome White Cast Grinding Ball (3)

3.Application effect and discussion

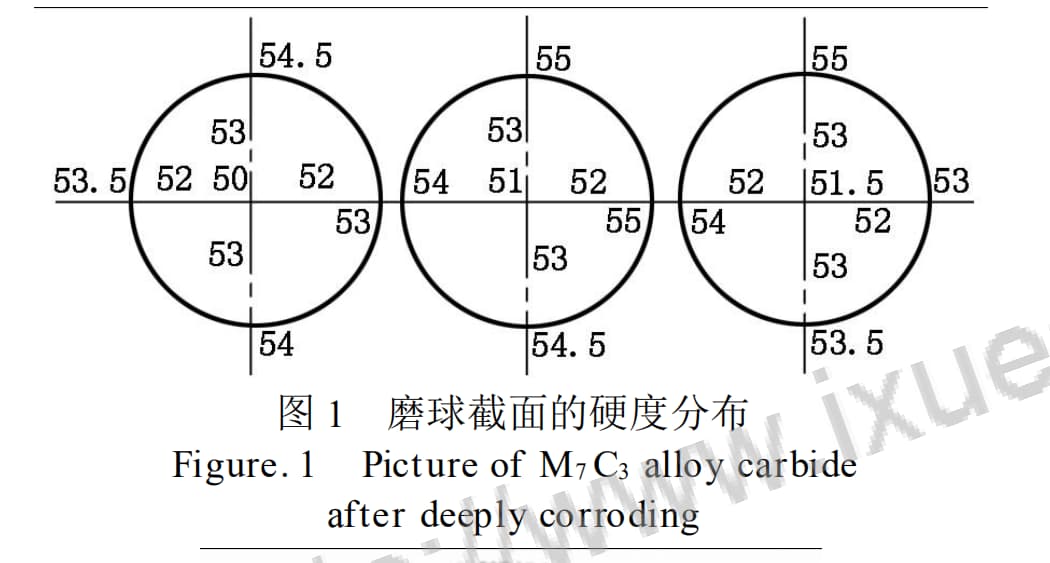

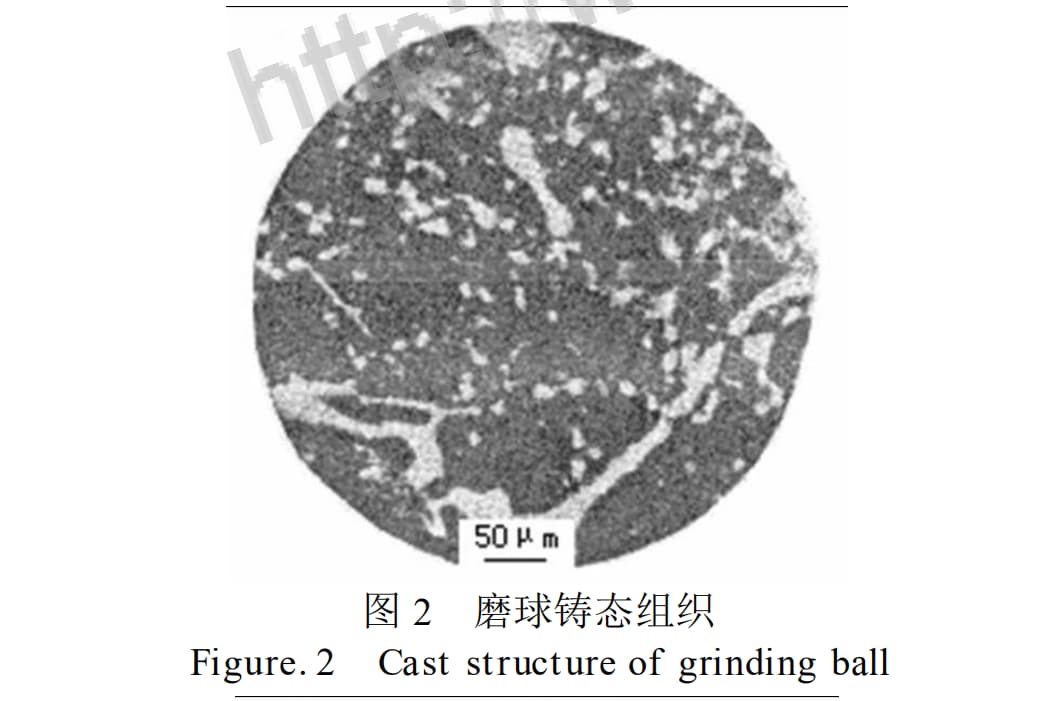

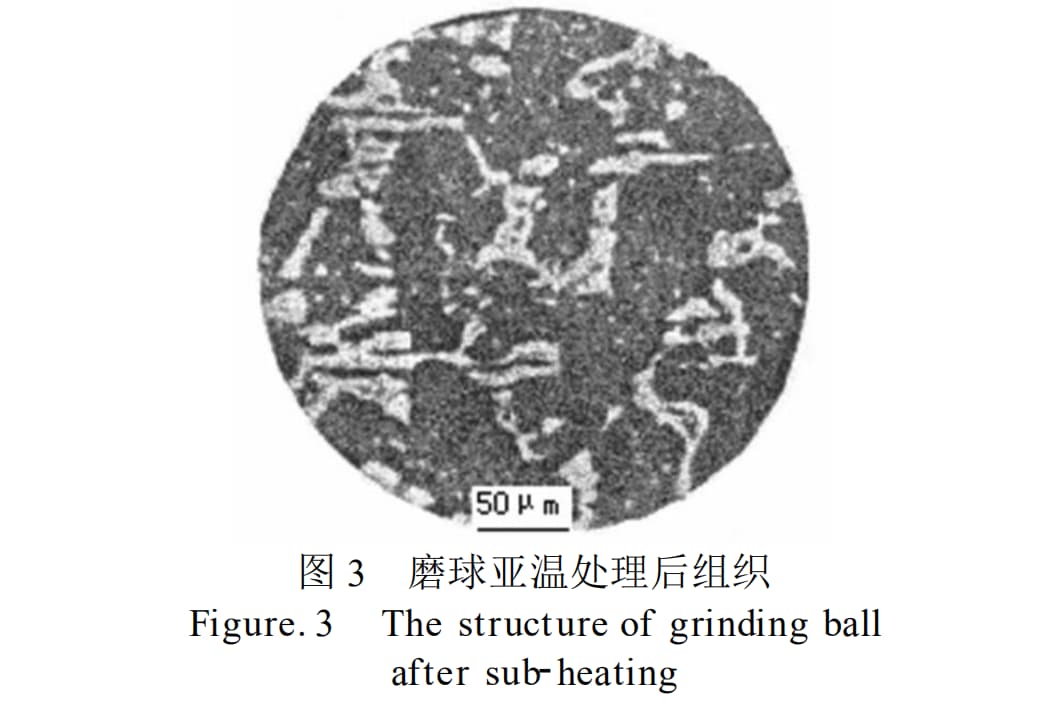

1) The mechanical properties and anti-fatigue, and impact properties of the white cast grinding balls are up to the expected values. The hardness distribution is shown in Fig. 1. The ball’s microstructure after as-cast and sub-temperature treatment is as shown in fig. 2 and Fig. 3.

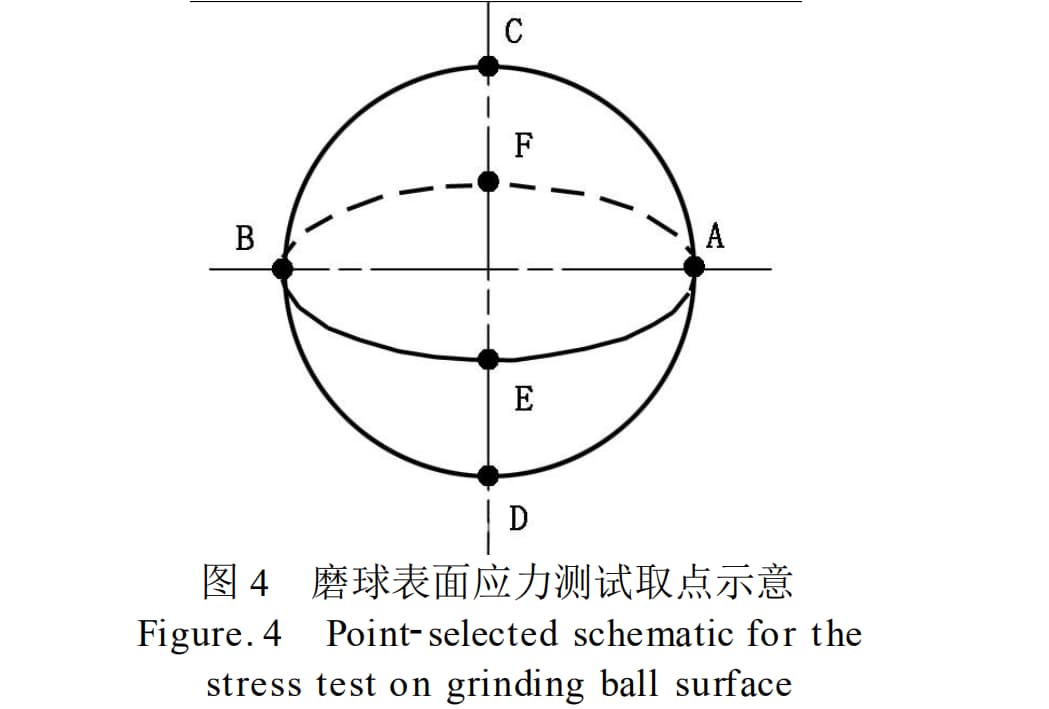

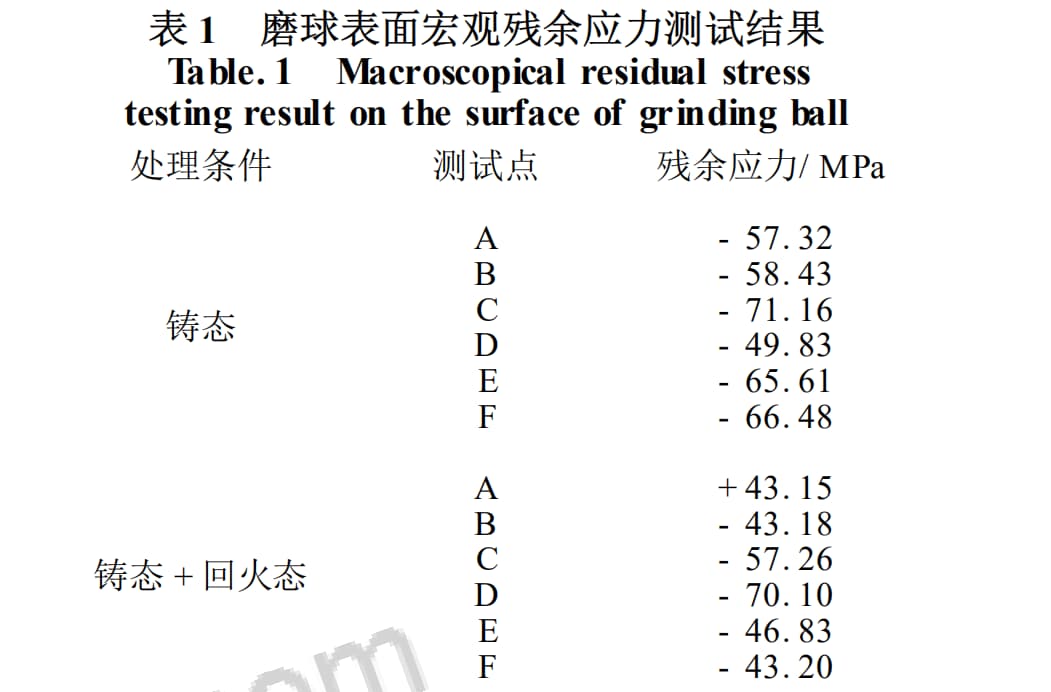

2). The X-Ray Stress Meter Xy-273 was used to measure 6 points, as shown in Fig. 4. The results are listed in Table 1. Because the high-temperature liquid in the solidification process blocks the solidification shrinkage of the surface of the white cast grinding ball, there is compressive stress on the surface of the ball.

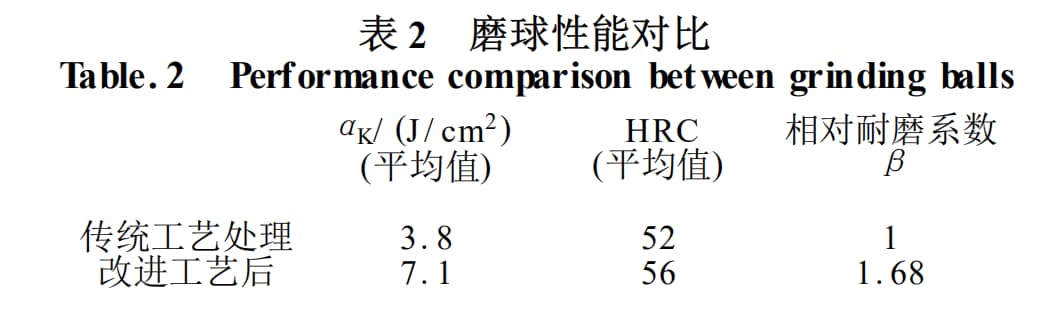

(3) After the metallurgical treatment of medium chromium white cast iron, the MLD21 impact abrasive wear machine is used to measure the relative wear life β value of medium chromium white cast grinding balls produced by the same process and the traditional process. The results are shown in Table 2.

As shown in Table 2, the mechanical properties and wear resistance have changed greatly.

Compared with the traditional process, the grinding ball has good toughness, high hardness and low stress, and service life and adaptability to working conditions.